TMC and SGS Produce World-First Nickel Sulfate from Deep-Seafloor Polymetallic Nodules

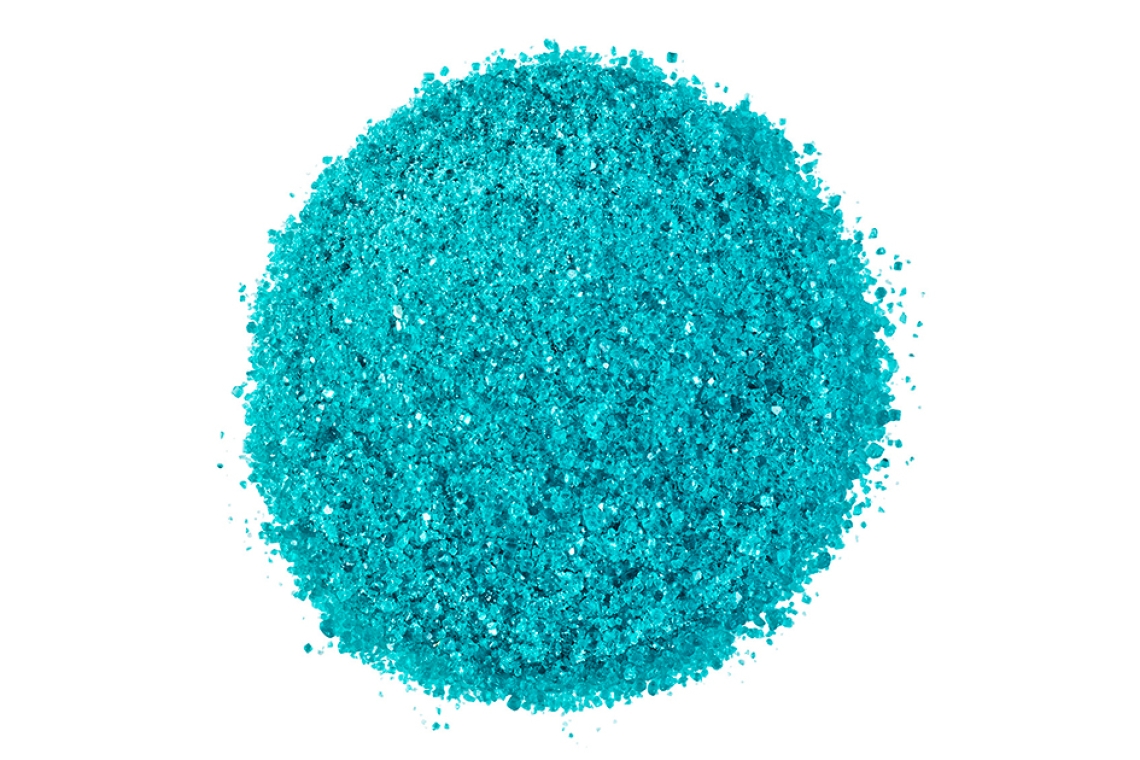

TMC (the metals company Inc.), an explorer of the world’s largest estimated undeveloped source of critical battery metals, announced that it has successfully produced the world’s first nickel sulfate derived exclusively from seafloor polymetallic nodules. The sulfate was generated during bench-scale testing of its hydrometallurgical flowsheet design in partnership with SGS Canada Inc., at their Lakefield, Ontario facility.

Undertaken on samples of nickel-cobalt-copper matte produced by TMC in 2021, the Extractive Metallurgy team at SGS tested TMC’s efficient flowsheet to process high-grade nickel matte directly to nickel sulfate without making nickel metal, while producing fertilizer byproducts instead of solid waste or tailings. Following the successful nickel sulfate production, SGS continues testing to produce what TMC believes will be the world’s first cobalt sulfate from polymetallic nodules.

Dr. Jeffrey Donald, TMC's Head of Onshore Development, said: “The production of the world’s first nickel sulfate from deep-seafloor nodules is an important milestone, confirming that our custom flowsheet configuration can be deployed to process these remarkable rocks into final products suitable for use in batteries. This work was executed in close collaboration with SGS and other industry leaders to demonstrate the ability to refine nodules to high value products. The data collected will inform further engineering decisions to move this towards commercial scale, and TMC continues to expect that initial production will begin with a capital-light approach by leveraging the existing processing facilities of strategic partners, such as PAMCO. With the commencement of this new industry now being seen as imminent by countries and companies alike, this represents not just a major achievement for TMC but for the entire deep-seafloor minerals industry.”

SGS North America Senior Director, Metallurgy & Consulting, Stephen Mackie, added: “As a trusted partner, SGS is proud to be working with the metals company to execute a key part of their initiative. The test work completed to-date for TMC has proven to be quite successful and we are excited on continuing our relationship with them on future phases of work.”

TMC’s NORI and TOML projects are ranked as the world’s #1 and #2 largest undeveloped nickel projects according to Mining.com, containing in situ quantities of nickel, cobalt, copper and manganese sufficient to meet the needs of 280 million electric vehicles—roughly the size of the entire US light vehicle fleet. With analysts warning that the quantities of critical battery metals like nickel and cobalt available from domestic or allied partners will be insufficient to meet US demand from the energy transition, there is increased interest in and prioritization of marine minerals to support energy and national security.

In March, members of the House of Representatives introduced draft legislation calling for the US to “provide financial, diplomatic, or other forms of support for seafloor nodule collection, processing and refining.” In November 2023, TMC signed a Memorandum of Understanding with Pacific Metals Corporation (PAMCO) to complete a feasibility study to process 1.3 million tons of wet polymetallic nodules (PMN) per year into high-grade nickel-copper-cobalt alloy/matte and manganese silicate, which are feedstock for the production of lithium-ion batteries, electrical infrastructure and steel.